AIR FLOW PATTERN TEST OR AIR FLOW VISUALIZATION TEST

ISO 14644 is a standard that provides guidelines for cleanrooms and controlled environments. It specifies various parameters and requirements for cleanroom air cleanliness, including air flow patterns. One commonly used method to test air flow patterns in cleanrooms is the use of a water fogger.

Here’s a step-by-step procedure for conducting an air flow pattern test using a water fogger according to ISO 14644:

Prepare the cleanroom: Ensure that the cleanroom is in the operational condition and all equipment is functioning properly. The cleanroom should be free from unnecessary obstructions and any loose particles.

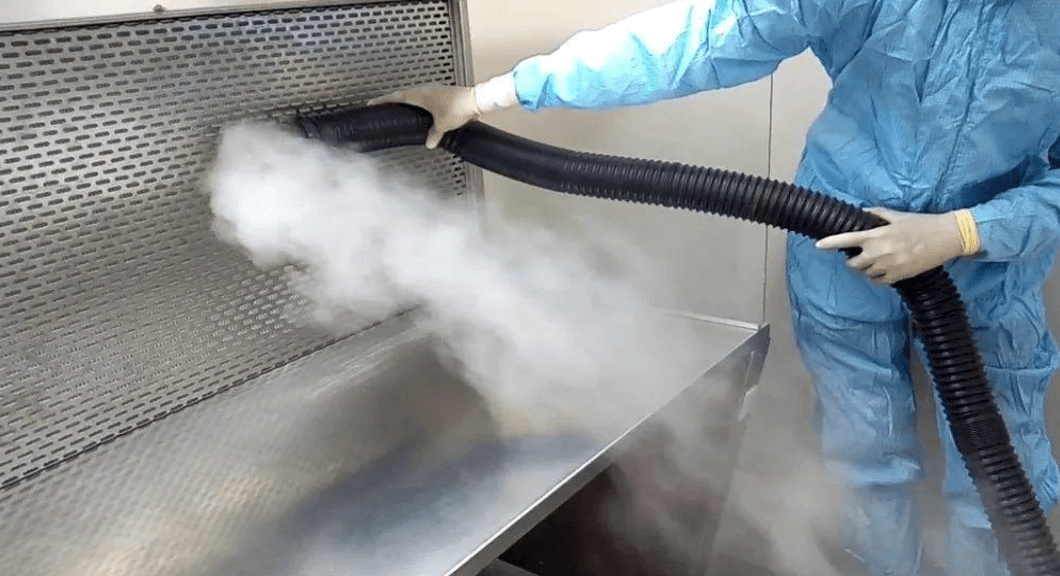

Set up the water fogger: Place the water fogger in a suitable location within the cleanroom. The fogger should be capable of producing a fine mist or fog that can be easily visualized.

Stabilize the cleanroom environment: Allow sufficient time for the cleanroom to stabilize, ensuring that the air conditioning, filtration, and other systems have reached steady-state conditions.

Activate the water fogger: Start the water fogger and adjust the fog generation to an appropriate level. The fog should be evenly dispersed throughout the cleanroom without excessive condensation or pooling.

Observe the air flow pattern: Walk through the cleanroom, systematically observing the movement and dispersion of the fog. Pay close attention to the direction and velocity of the air as indicated by the fog movement.

Document the observations: Record the air flow pattern observations in a structured manner. Note any areas of turbulence, dead spots, or uneven air distribution that may be identified during the test.

Analyze the results: Compare the observed air flow pattern with the desired or specified air flow pattern for the cleanroom class. ISO 14644 provides specific guidance on the acceptable air flow patterns for different cleanroom classes.

Take corrective actions if necessary: If any deviations from the desired air flow pattern are identified, appropriate corrective measures should be taken. This may involve adjusting the location or configuration of air supply diffusers, exhaust grilles, or other components of the ventilation system.

Repeat the test if needed: In case significant deviations or concerns persist, the air flow pattern test can be repeated after implementing corrective actions to ensure compliance with the required standards.

Remember that this is a general procedure, and specific requirements may vary based on the cleanroom class, size, and design. It’s essential to consult the ISO 14644 standard and any additional guidelines or regulations applicable to your particular cleanroom facility.